Evolution of Subcontracting in ERPNext: A Comparison from V13 to V15

Subcontracting is a critical component of many manufacturing and production processes, allowing businesses to outsource specific tasks or components to external vendors. ERPNext, a comprehensive open-

Introduction

In the ever-evolving world of enterprise resource planning (ERP) systems, managing subcontracting efficiently is crucial for businesses that rely on external partners to streamline their production processes. ERPNext, a powerful open-source ERP solution, has continuously improved its subcontracting features across different versions to meet the growing demands of modern businesses. Whether you're a manufacturer, distributor, or service provider, understanding how subcontracting functionality has evolved in ERPNext can help you optimize your operations and stay ahead of the curve.

In this blog, we’ll take a closer look at how subcontracting has been enhanced in ERPNext versions 13, 14, and 15. From improved workflows and user experience to advanced features and integrations, each version brings something new to the table. Whether you're considering an upgrade or simply curious about the changes, this comparison will provide valuable insights into how ERPNext has refined its subcontracting capabilities over time. Let’s dive in!

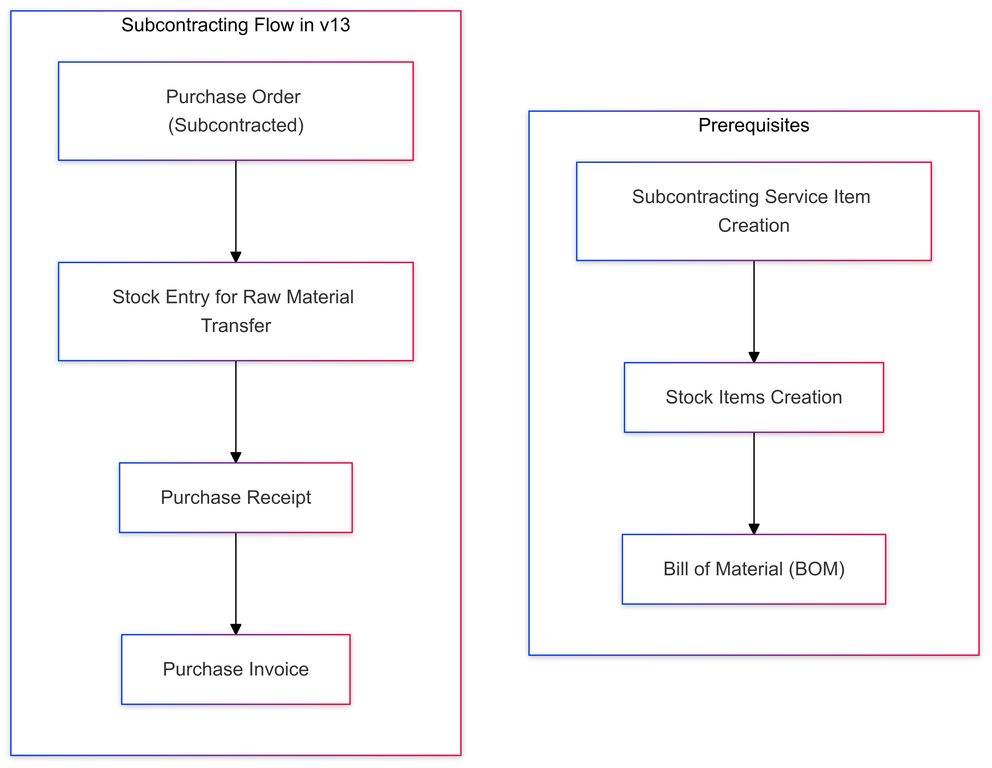

Subcontracting in ERPNext V13

In ERPNext V13, the subcontracting process follows a straightforward flow:

- Purchase Order (Subcontracted): The process begins with creating a Purchase Order for subcontracted items. This order specifies the items to be manufactured by the subcontractor.

- Stock Entry for Raw Material Transfer: Once the Purchase Order is confirmed, a Stock Entry is created to transfer the raw materials required for production to the subcontractor.

- Purchase Receipt: After the subcontractor completes the production, a Purchase Receipt is generated to acknowledge the receipt of the finished goods.

- Purchase Invoice: Finally, a Purchase Invoice is created to bill the subcontractor for the services rendered.

Prerequisites:

- Subcontracting Service Item Creation: A service item must be created to represent the subcontracting service.

- Stock Items Creation: Raw materials and finished goods must be defined as stock items.

- Bill of Material (BOM): A BOM is required to specify the raw materials needed for production.

Screen Shot of Subcontracting workflow in ERPNext V13

Key Points:

- The process in V13 is relatively simple but lacks some advanced features.

- The absence of a dedicated Subcontracting Order can make tracking and managing subcontracting tasks less efficient.

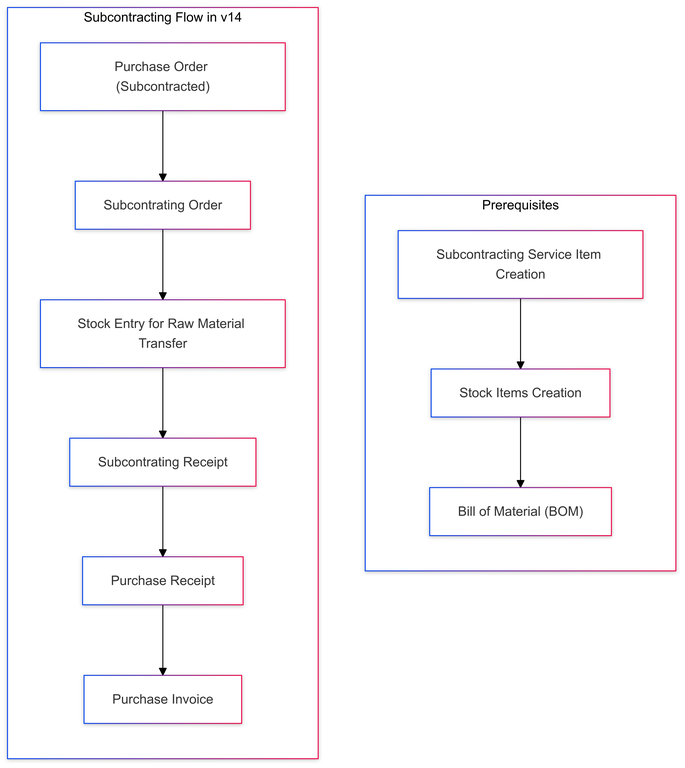

Subcontracting in ERPNext V14

ERPNext V14 introduced significant improvements to the subcontracting process, making it more structured and easier to manage:

- Purchase Order (Subcontracted): Similar to V13, the process starts with a Purchase Order for subcontracted items.

- Subcontracting Order: A new feature in V14, the Subcontracting Order, is created to track the specific details of the subcontracting task. This order helps in better monitoring and management of the subcontracting process.

- Stock Entry for Raw Material Transfer: Raw materials are transferred to the subcontractor using a Stock Entry.

- Subcontracting Receipt: After production, a Subcontracting Receipt is generated to acknowledge the receipt of finished goods.

- Purchase Receipt and Purchase Invoice: The process concludes with the creation of a Purchase Receipt and Purchase Invoice.

Prerequisites:

- Subcontracting Service Item Creation: A service item for subcontracting is required.

- Stock Items Creation: Raw materials and finished goods must be defined.

- Bill of Material (BOM): A BOM is needed to specify the raw materials.

Screenshot of Subcontracting flow in ERPNext V14

Key Points:

- The introduction of the Subcontracting Order in V14 provides better tracking and control over subcontracting tasks.

- The process is more streamlined, with clear documentation at each stage.

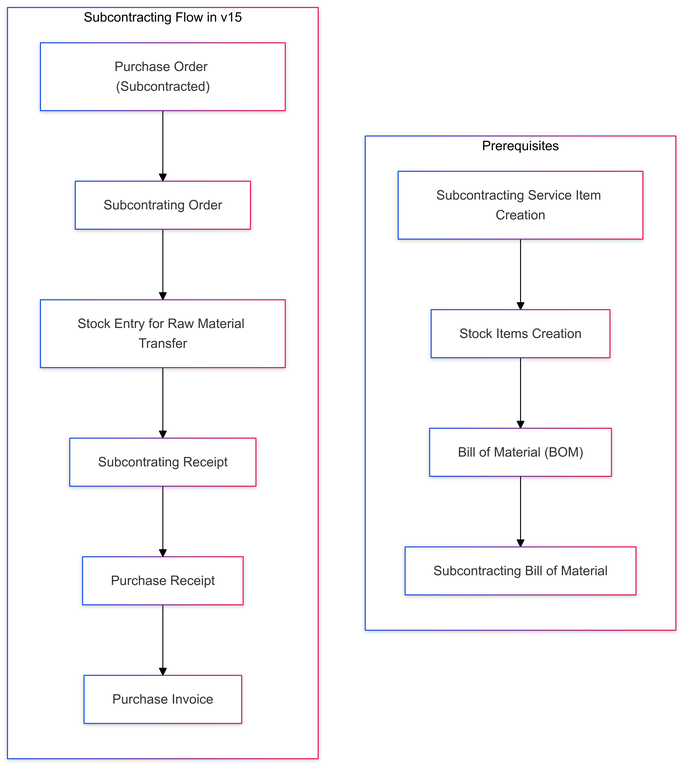

Subcontracting in ERPNext V15

ERPNext V15 further enhances the subcontracting process with additional features and refinements:

- Purchase Order (Subcontracted): The process begins with a Purchase Order for subcontracted items.

- Subcontracting Order: Similar to V14, a Subcontracting Order is created to manage the subcontracting task.

- Stock Entry for Raw Material Transfer: Raw materials are transferred to the subcontractor using a Stock Entry.

- Subcontracting Receipt: A Subcontracting Receipt is generated to acknowledge the receipt of finished goods.

- Purchase Receipt and Purchase Invoice: The process concludes with the creation of a Purchase Receipt and Purchase Invoice.

Prerequisites:

- Subcontracting Service Item Creation: A service item for subcontracting is required.

- Stock Items Creation: Raw materials and finished goods must be defined.

- Bill of Material (BOM): A BOM is needed to specify the raw materials.

- Subcontracting Bill of Material: A new feature in V15, the Subcontracting BOM, allows for more detailed and specific BOMs tailored for subcontracting tasks.

Screenshot of Subcontracting Workflow in ERPNext V15

Key Points:

- The addition of the Subcontracting BOM in V15 provides greater flexibility and precision in defining the materials and processes for subcontracting.

- The process remains streamlined, with enhanced documentation and tracking capabilities.

Rizwan Ahmed

Certified ERPNext Functional Consultant

No comments yet. Login to start a new discussion Start a new discussion