Advance Stock Management Part I: Put away Rule

Put away rule basically defined a warehouse assignment strategy, which helps automate warehouse assignment when inventory is procured or transferred.

Introduction

Put away rules in ERPNext streamline stock management by automatically determining the most suitable location for storing inventory based on the defined capacity and priority of warehouses. Let’s explore how this feature functions with an example.

Imagine that stock manager receives a replenishment request for paper. After reviewing the current stock levels in ERPNext, he decides to order 500 units of paper to meet the demand. However, at the time of loading, workers discover that there are 10 warehouses, each with multiple racks and bins allocated for paper. Some of these locations have limited storage capacity.

This is where ERPNext's Put away Rules come into play. The system automatically decides where the newly procured inventory should be placed, simplifying the process for users. Below, we’ll demonstrate how warehouse assignments are managed using ERPNext’s Put away Rules.

How Put away Rules Function in ERPNext

1. Setting Up Put away Rules

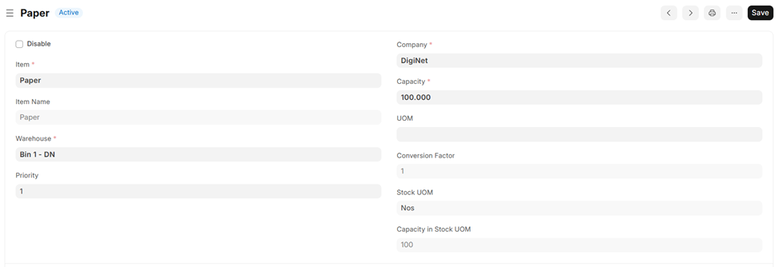

Example: Rule 1:

- Warehouse: BIN 1 – DN

- Capacity: 100

- Priority: 1

Screenshot of configuring put away rule in ERPNext.

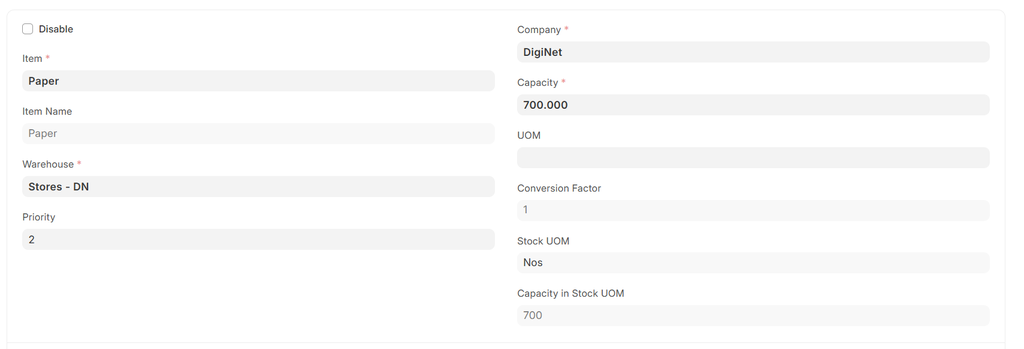

Example: Rule 2:

- Warehouse: Stores

- Capacity: 700 (300 already filled)

- Priority: 2

Screenshot of configuring put away rule in ERPNext.

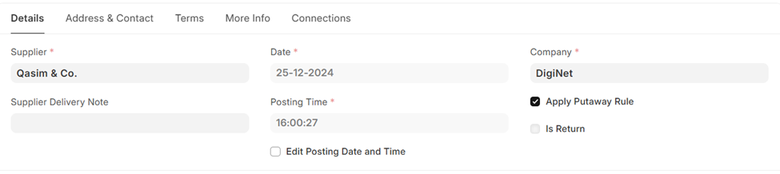

2. Applying Put away Rules

When a stock user enters a purchase receipt and selects the checkbox to apply the putaway rule, ERPNext automatically assigns the inventory to warehouses based on the predefined rules.

Screenshot of put away rule being Applied in Purchase Receipt.

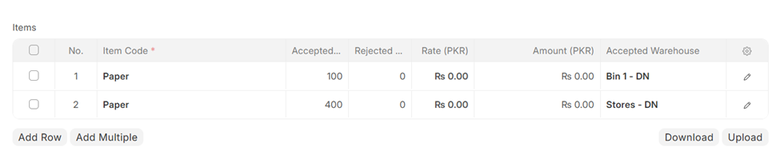

3. Auto-Warehouse Assignment and Quantity Distribution

ERPNext ensures that inventory is distributed efficiently among the warehouses, respecting the capacity limits and priority levels set in the Putaway Rules. (Orignal Order was for 500 Paper)

Screenshot of ERPNext auto-allocating warehouse and inventory distribution in purchase receipt.

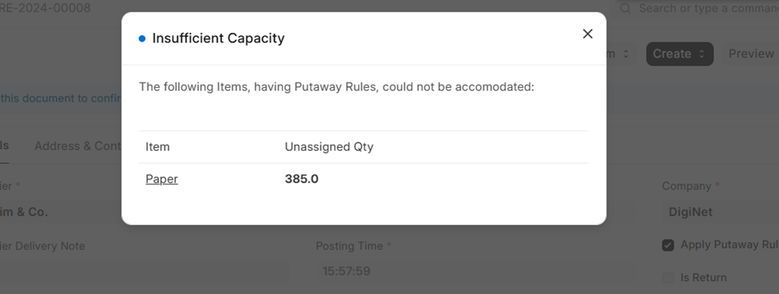

4. Handling Overcapacity

If the user attempts to accept a quantity exceeding the warehouse’s capacity, the system displays an error message alerting the user to revise the allocation or adjust the quantities.

Screenshot of error message, in case of over receipt then warehouse capacity.

Conclusion

ERPNext’s Putaway Rules are an essential tool for efficient stock management, particularly in complex warehouse setups. By automating warehouse assignments and ensuring optimal utilization of storage space, this feature reduces manual effort, minimizes errors, and enhances inventory accuracy. Businesses can use this functionality to streamline operations and make their supply chain more efficient.

This concludes Part I of our series on Advanced Stock Management. Stay tuned for more insights into ERPNext’s powerful features!

Rizwan Ahmed

Certified ERPNext Functional Consultant

No comments yet. Login to start a new discussion Start a new discussion